Why Do Batteries Explode? Causes, Prevention Tips & Safety Guide

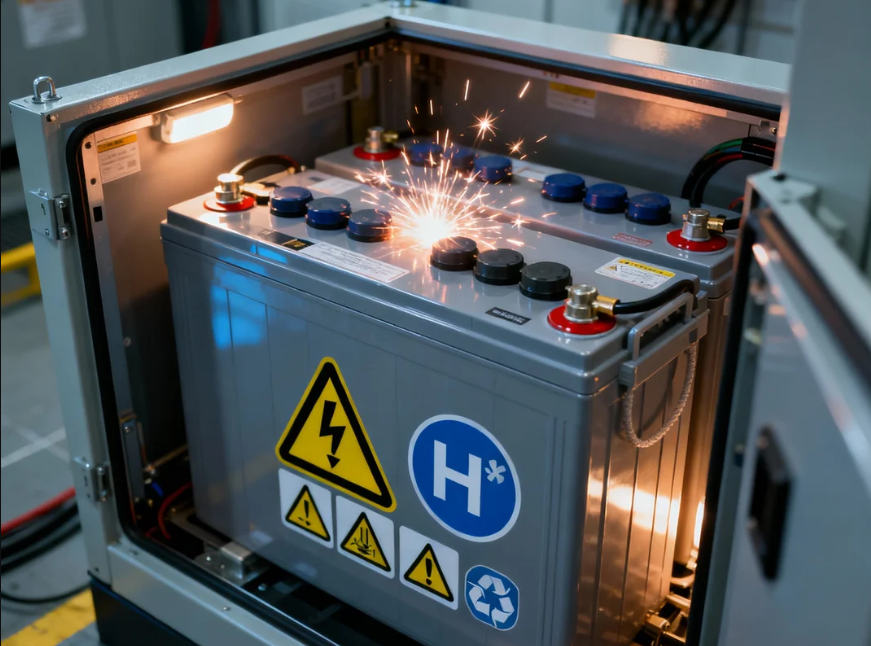

Why Can Lead-Acid Batteries Explode?

Lead-acid batteries without a battery box will not “explode”, but the reason why the battery will “explode” after being installed in the battery box is because:

1) The power supply box is too sealed, and the hydrogen generated at the end of the battery charging cannot escape;

2) The power connection line is loose, aging or exposed, sparks are generated when the key is turned on, or the line generates sparks to ignite hydrogen due to uneven road vibration;

3) The fuse holder on the power box body is loose, and it generates heat or sparks during the charging and discharging process of the battery, ignites the hydrogen gas to produce gas expansion, and breaks the upper cover of the battery;

The Chemical Mechanism of Hydrogen Evolution

The risk of explosion in lead-acid batteries primarily stems from the build-up of flammable hydrogen gas H₂. This gas is generated during the charging process, especially when the battery reaches its fully charged state and undergoes overcharging or gassing.

At the cell level, water in the electrolyte undergoes electrolysis:

Negative Plate: 2H++ 2e- → H2 ↑ (Hydrogen Gas)

Positive Plate: H₂O → ½O₂ ↑ + 2H⁺ + 2e⁻ (Oxygen Gas)

In a sealed or poorly ventilated enclosure, this gas mixture of H₂ and O₂ can accumulate rapidly, creating a highly volatile atmosphere.

The Critical Danger: Explosive Limits and Ignition Sources

The true danger lies in the concentration of hydrogen relative to air:

Lower Explosive Limit (LEL): Hydrogen becomes explosive when its volume concentration in air reaches 4.0%.

Minimum Ignition Energy (MIE): Hydrogen has an extremely low MIE, approximately 0.02 millijoules mJ. This means even a tiny spark—far too small to ignite most common gases—can trigger a massive explosion.

Common Ignition Sources in Battery Boxes:

- Loose Connections: High resistance in wiring or terminals generates heat and sparks upon system activation or road vibration.

- Faulty Fuses/Holders: Loose or aged fuse connections can arc during high current flow.

- Static Electricity: Especially dangerous when opening or closing the battery box.

Engineering Mitigation and Compliance Standards

Global Safety Mandates (NFPA, IEC, UL)

Effective battery explosion prevention goes beyond simple venting holes; it requires strict adherence to global engineering and fire safety standards:

NFPA 70 (National Electrical Code, Article 480): Requires that ventilation for battery rooms or enclosures be designed to limit the concentration of hydrogen gas to 25% of the LEL (i.e., a maximum of 1.0% hydrogen concentration by volume).

IEC 62485-2 (Safety requirements for secondary batteries): Provides specific formulas and guidelines for calculating the required ventilation rate (Q) to ensure safety margins are maintained during the highest gassing periods (e.g., boost or equalization charging).

UL 1973: Safety standard for stationary batteries, which incorporates requirements for thermal and mechanical integrity, as well as necessary venting provisions.

Designing for Safety: Ventilation Calculation

A qualified engineering assessment is necessary to determine the required ventilation rate (Q in m³/h). A fundamental calculation, derived from international standards, often looks like this:

Q = 119 x Igas x n x k

Where:

Igas : Maximum gassing current (Amperes).

n: Number of battery cells in series.

k: Safety factor (typically between 5 and 10 to ensure the 1.0% H2 concentration limit is met).

Key Takeaway: Simply drilling a few holes is insufficient. Proper prevention requires calculated airflow (natural convection or mechanical exhaust) that guarantees the H₂ concentration remains safely below the 1.0% threshold, validated by engineering compliance.

How to Avoid Battery Explosion

Implementing the following battery management practices can dramatically reduce risk:

1) The power box should not be too sealed during design. Several convection vents with a diameter of about 1cm should be provided on the upper and lower parts of the battery box to facilitate the discharge of gas generated during charging;

2) If the power box is designed without ventilation holes, the ventilation holes must be reserved during installation;

3) Regularly check the power wiring to prevent loosening, aging or exposure;

4) If the fuse holder is found to be loose and aging, replace it in time.

Recommended Battery Solutions for Safety and Long-Term Reliability

To ensure safety and longer service life, selecting products with advanced protection systems is essential.

At Vanyo Energy, we provide energy storage solutions with:

- Integrating smart inverters

- Lithium-ion batteries

- MPPT controllers

- Unified energy management platform

Explore our products:

Commercial & Industrial BESS Systems

Want Safer, Certified Energy Storage Systems?

The complexities of managing hydrogen evolution highlight why modern energy storage solutions are shifting towards advanced technologies. Our Vanyo Energy Lithium-ion BESS Systems are engineered with multi-layered protection, including smart, active cooling, thermal runaway mitigation, and integrated Battery Management Systems (BMS) to eliminate the hazards associated with gas accumulation and loose connections.Choosing the right battery system reduces fire and explosion risks.If you need OEM/ODM support, custom BESS solutions, or technical advice, our team is ready to help.

Contact us today:

info@vanyoenergy.com

Battery explosions are preventable. With proper ventilation, electrical inspection, and certified energy storage solutions, users can effectively eliminate risks and ensure long-term safety.

Home

Home

Harnessing the Future with Advanced Power Station Solutions

Harnessing the Future with Advanced Power Station Solutions

Address: Wanyang Gold and Silver Building 6, Circular Economy Park, Sili Town, Jiyuan City, Henan Province, China

Address: Wanyang Gold and Silver Building 6, Circular Economy Park, Sili Town, Jiyuan City, Henan Province, China